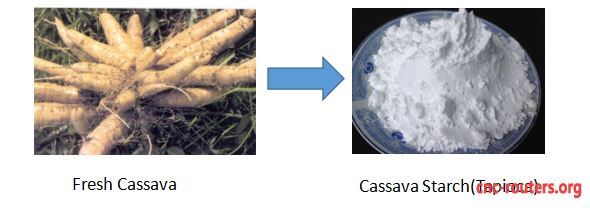

Features of Cassava Starch Machine

Cleaning and Washing Cassava (tapioca) Roots

Wash the fresh cassava (tapioca) roots in clean water to remove the surface mud and sand. It's the first step of cassava starch process and very important for the quality of final cassava starch(tapioca).

Peeling Cassava (tapioca) Roots

Peel the washed cassava (tapioca) roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Crushing Peeled Cassava (tapioca) Roots into Slurry

Crushing the peeled cassava (tapioca) roots into the slurry and separate to remove the coarse cassava residues to obtain uniformly smooth cassava slurry. The crushing drum and all food contact areas should be made from stainless steel.

Cassava (tapioca) Slurry and Residues Separation

The commonly physical operation to separate fine cassava residues from cassava slurry. Oversize particles of cassava residues cannot pass through the lattice structure of the filter, while fluid and small particles of cassava slurry can pass through to become filtrate.

Raw Starch Milk Desanding and Desilting

Solid control equipment that separates tiny sand and mud from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Starch Refining and Concentrating

When raw starch milk enters the hydrocyclone, the pure starch milk of high density getting larger centrifugal force leaves from the underflow outlet, and the protein and other soluble impurities of low density getting smaller centrifugal force leave from the overflow outlet. Finally, achieve the purpose of various components of separation, and improve the quality of final starch with higher whiteness and purity.

Pure Starch Milk De-watering

De-watering the pure starch milk to low water content of 35-40% by the principle of vacuum suction filtration. Ensure sufficient water has been removed, otherwise, the starch will form into lumps during drying.